La Tramontane - Ferienhaus direkt am Meer

Global Industrial Machine Vision Market size is expected to reach US$ XX Bn. by 2026 from US$ XX Bn. in 2019, at a CAGR of 9.6% during the forecast period.

Global Industrial Machine Vision Market Introduction and Market scenario:

Machine vision includes the grouping of various software and hardware that guides operational devices to capture and process image.

The high demand for industrial IoT and artificial intelligence infused machine vision systems is the main driving factor for the growth of the industrial machine vision market over the forecast period (2020-2026). Also, the rise in the requirement for quality inspection & automation and high adoption of 3D machine vision systems are the factors that contribute to the growth of the industrial machine vision market.

The machine vision system helps in supervising work environments as it offers several features such as robotic guidance, automatic inspection, and process control in industrial applications such as vision-guided robotics systems, inspection in food and packaging industries, and an increase in government initiatives to boost AI-related technologies. Additionally, the rise in requirement for reduction of cameras and processors as well as high adoption of Industry 4.0 and increase in manufacturing of hybrid and electric cars are expected to produce significant growth opportunities in the industrial machine vision market in the forecasted period.

On the other hand, the lack of flexible machine vision solutions along with the deficiency of skilled professionals in manufacturing factories are the major restraining factors for the growth of industrial machine vision in the future. Moreover, the lack of user awareness concerning the fast change in machine vision technology and varying end-user requirements may challenge the industrial machine vision market growth in the forecast period (2020-2026).

COVID-19 Impact on the Global Machine Vision Market:

Manufacturing firms are introducing automation to improve operating efficiency in their day-to-day functions. By the production of products during the pandemic, where human interactions have limited, machine vision technology has helped ensure continuity of production. Additionally, the machine vision industry plays a vigorous role in the fight against COVID-19 through automated lab systems that process and test vaccines, thermal imaging to detect body temperature in crowded locations, inspection systems, pharmaceuticals, and medical products. Then again, the pharmaceutical industry is stated to be an early adopter of machine vision technology as it provides product safety assurance as well as integrity to the current digital infrastructure.

The demand for machine vision technology is an escalation during the ongoing COVID-19 pandemic. On the other hand, this demand is expected to be slowed down by the reduction in IT expenditure budgets as a result of the lockdowns, as well as the serious losses incurred by companies worldwide. While relaxation in the lockdowns is expected to increase in the demand for machine vision infrastructure, the market is recovering at a significant pace, because of the remote work policy adopted by many companies to stop the spread of COVID-19. These industries belong to several sectors, such as textiles, agriculture, pharmaceuticals, and other mass-production industries, which need quality assurance. Thus, the demand for machine vision technology and its related infrastructure is expected to increase due to the growing adoption of digital assurance mechanisms that offer higher accuracy and operational efficiency compared to human beings.

Global Industrial Machine Vision Market Segment Overview:

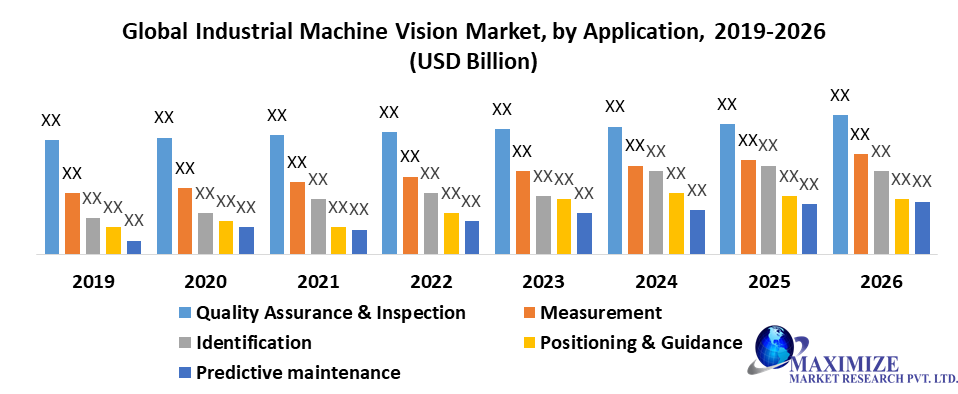

The quality assurance and inspection application segment are expected to hold the largest market share of the global market by 2026. This growth is attributed to industries have understood the importance of quality assurance in manufacturing processes, which has resulted in the extensive acceptance of machine vision as an integral part of the long-term automation development process.

Automotive industry is expected to grow at the highest CAGR of XX% during the forecast period. This is mainly because the machine vision system provides improved accuracy in critical activities, including bin picking and positioning of parts, such as doors and panels, for assembly, in the automotive sector. Due to the lack of a skilled workforce and the reducing manufacturing prices of automobiles, automobile companies are concentrating more on automation in their production processes.

Global Industrial Machine Vision Market

To know about the Research Methodology :- Request Free Sample Report

Global Industrial Machine Vision Market Regional Insights:

The Asia Pacific is dominating the global market with above 30% of the market share, followed by Europe, which is the second-largest market because of the strong demand from the automotive and healthcare industries. APAC's machine vision market is expected to hold the largest market share during the forecast period, thanks to APAC countries such as India, China, Japan, and South Korea has the largest manufacturing facilities where automation of manufacturing processes have been given the highest priority. Also, strong competition between consumer electronics companies in APAC is expected to fuel the adoption of machine vision systems in the Asia Pacific.

Conversely, the outbreak of COVID-19 has a major effect on the manufacturing sector of APAC. As the neighboring countries are interconnected through trade relations and the supply chain, the overall region is affected by the outbreak of COVID-19, which is expected to have a major effect on the demand in the Asia Pacific during the forecast period.

North America is the third-largest market. Thanks to the implementation of advanced technology in numerous industries.

Global Industrial Machine Vision Market Regional Insights

Recent Industry Developments:

• In May 2020, Cognex launched the Insight D900 embedded vision system. The system is the first-of-its-kind solution, as it features Cognex's ViDi deep learning software within the In-Sight industrial-grade smart camera. The self-contained system is designed to solve a wide range of complex in-line inspection applications, like optical character recognition (OCR), assembly verification, and defect detection.

• In February 2020, Basler released its latest AI Vision Solution Kit with Cloud Connection. Extends embedded vision development kits with software components that allow flexible access to cloud services. The AI Vision Solution Kit will enable developers to use, train and deploy machine learning models provided in the cloud on the edge device. For this reason, pre-trained neural networks are made available in the cloud as software containers designed for direct use. Users will have the option to extend these networks.

• In November 2019, National Instruments announced new solutions for hardware-in-the-loop (HIL) validation of electric vehicle (EV) powertrain components. High-performance EV HIL systems require coordination from multiple vendors. NI works with companies like OPAL-RT, with its advanced eHS electrical solver and electric machine library, to help ensure seamless high-fidelity model integration. Seamless integration of OPAL-RT models with the test system can help reduce test development times while increasing result resolution, helping customers achieve shorter design cycles, and gain better insights from test data.

• In October 2019, Cognex Corporation announced the acquisition of SUALAB, a leading Korean-based developer of vision software using deep learning for industrial applications. The addition of SUALAB’s engineering team and intellectual property will help to enhance Cognex’s existing deep learning capabilities based on technology acquired from ViDi Systems in April of 2017.

• In July 2019, Basler expanded its 3D Camera Portfolio with Basler blaze. With Sony DepthSens ToF technology, the Basler blaze with GigE interface and VGA resolution is particularly suitable for measuring the position, location, and volume of objects and for detecting obstacles. It can be used in a variety of industrial environments.

• In February 2019, Omron launched the FHV7-series smart camera for machine vision applications. The FHV7-series smart camera features a multi-color light, an autofocus lens, and a range of CMOS image sensors to serve inspection of varied products on single production lines. The camera also features a dual-core CPU and high-speed image compression algorithm that enables the saving of image data while inspecting a second image in parallel.

The report focuses on the Industrial Machine Vision market value at the top regions and countries of the world, which shows a regional development, including market size, share, revenue, and much more across the globe. The report has covered, capacity, production value, cost/profit, and supply/demand by statistical analysis. A brief analysis of drivers, restraints, opportunities, and challenges in the market is also covered with examples by region. To make the most of the opportunities, market vendors should focus more on the growth prospects in the fast-growing segments, while maintaining their positions in the slow-growing segments. It also has covered the analysis of key player’s growth strategies, micro and macro analysis of markets, key developments, and key trends in the market.

Global Industrial Machine Vision Market, Key Highlights:

• Global Industrial Machine Vision Market analysis and forecast, in terms of value.

• Comprehensive study and analysis of market drivers, restraints and opportunities influencing the growth of the Global Industrial Machine Vision Market

• Global Industrial Machine Vision Market segmentation on the basis of type, source, end-user, and region (country-wise) has been provided.

• Global Industrial Machine Vision Market strategic analysis with respect to individual growth trends, future prospects along with the contribution of various sub-market stakeholders have been considered under the scope of study.

• Global Industrial Machine Vision Market analysis and forecast for five major regions namely North America, Europe, Asia Pacific, the Middle East & Africa (MEA) and Latin America along with country-wise segmentation.

• Profiles of key industry players, their strategic perspective, market positioning and analysis of core competencies are further profiled.

• Competitive developments, investments, strategic expansion and competitive landscape of the key players operating in the Global Industrial Machine Vision Market are also profiled.

The report has considered the base year of 2019 and past four years trend. 2020 figures are at actuals, however due to different dynamics of year 2020, market forecast is not only dependent upon 2020, but on the basis of 2016-2020.

Global Industrial Machine Vision Market Scope: Inquire before buying

Global Industrial Machine Vision Market

Global Industrial Machine Vision Market, by Region

• North America

• Europe

• Asia Pacific

• Middle East & Africa

• South America

Global Industrial Machine Vision Market Key Players

• Cognex Corporation

• Basler AG

• Omron Corporation

• Keyence

• National Instruments

• Sony Corporation

• Teledyne Technologies

• Texas Instruments

• Intel Corporation

• ISRA Vision

• Sick AG

• FLIR Systems

• Allied Vision Technologies GmbH

• SICK AG

• Baumer

• JAI A/S

• MVTEC SOFTWARE GMBH

• Tordivel AS

• AMETEK Surface Vision

• Qualitas Technologies Pvt. Ltd.

• Cadence Design Systems, Inc.

• Aquifi

• LMI Technologies

• Prophesee

• 3D Infotech

• VAIA Technologies

For More Information Visit @:

https://www.maximizemarketresearch.com/market-report/global-industr...

This Report Is Submitted By : Maximize Market Research Company

Customization of the report:

Maximize Market Research provides free personalized of reports as per your demand. This report can be personalized to meet your requirements. Get in touch with us and our sales team will guarantee provide you to get a report that suits your necessities.

About Maximize Market Research:

Maximize Market Research provides B2B and B2C research on 20,000 high growth emerging opportunities & technologies as well as threats to the companies across the Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.

Seitenaufrufe: 1

Kommentar

© 2024 Erstellt von Jochen und Susanne Janus.

Powered by

![]()

Sie müssen Mitglied von Korsika sein, um Kommentare hinzuzufügen!

Mitglied werden Korsika